forums.danceScape.com

forums.danceScape.com  Forums - Live, Love, Laugh ... Dance!

Forums - Live, Love, Laugh ... Dance!  danceScape SkyhiClub Lounge: Welcome to the Skyhi Life!

danceScape SkyhiClub Lounge: Welcome to the Skyhi Life!  FASHION

FASHION  The Dress Project -- Step-by-Step Ballgown Construction

The Dress Project -- Step-by-Step Ballgown ConstructionGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| Championship Registered:: 12-19-2000 Posts: 1328 | Hi everyone, I'm working on a new dress, this one for Three Step's partner, so I thought I'd use it as an opportunity to take dressmaking newbies through a project step-by-step. If you have any questions along the way, please ask here or at least send a private message! A few notes before I start... I use a Viking-Husqvarna 350 machine, and stitch about 95% of everything using their basic zig-zag stitch, #3. For thread I swear by Gutermann. I've tried other, less expensive, brands, and this is the best to me by far. I do all my cutting with a rotary cutter and a cutting mat, except for long pieces that are too big for a mat. I cut those with straight scissors. I never pin pattern pieces down, but instead use pattern weights. If you don't have pattern weights, small tin cans (like tunafish or cat food size) will work perfectly). I rarely cut out a pattern piece directly, instead I transfer the pattern to white tissue paper, the kind you wrap presents with. You'll see why when I start talking about pattern alterations. I can't recommend Kerstin Martensson's "Swim and Action Wear" from Kwick-Sew enough. If you don't have a lot of sewing experience, especially on stretch fabrics, I highly suggest that you get this book and make a leotard or two to get comfortable. I use her techniques for altering patterns, for sewing and finishing seams, and for installing elastic. This book is worth every penny and then some. At this point I haven't actually chosen a pattern for the main dress, so I'll talk about that when I get there. Laura [ 01-07-2002: Message edited by: Laura La Gassa ] |

| Championship Registered:: 12-19-2000 Posts: 1328 | Step One: Measurements I started out by taking Swivel's measurements. I use a plastic tape measure, and measured her in her underwear and stocking feet. I made sure that the tape was flat and snug but not so tight that it was pressing into her skin. I took: Bust (at widest part) I think that's all the ones I need! When you measure, take each measurement three times to ensure some semblance of accuracy. Laura [ 01-07-2002: Message edited by: Laura La Gassa ] |

| Championship Registered:: 12-19-2000 Posts: 1328 | Step Two: Test Leotard I really love working with the basic master leotard pattern from Kwik Sew's "Swim and Action Wear" book. So, my next step was to make a basic sleeveless tank leotard from Swivel's measurements (need Bust, Waist, Hips, Rise, Neck to Waist). I'm assuming that you are working from this book for this step -- the instructions in the book cover basic pattern alterations that you might need to make if someone is between sizes, has a long or short torso, or is high or low waisted. It is very important that you make the test leotard out of the same fabric as what you will use for the actual dress. If not the exact same fabric, then use something that has the same stretch characteristics. The point of the test leotard is to see if you are using the correct size for the fabric you have chosen. Some fabrics are stretchier up and down than across, and some are more stretchy up and down than others. I will be using slinky for the final dress, which has a lot of crosswise stretch but not a lot of up-and-down stretch. It is very likely that I will have to make adjustments to take this lack of up-and-down stretch into account :-) When I make the leotard I just sew all the seams with a medium-wide zig-zag basting stitch (length 3.0, width 3.0). I sew everything with 10mm seams (that's the way my throatplate is marked). I do not bother putting in the leg, neckline, or armhole elastic. There's no sense in finishing off the garment like that because this is just a test. Here is the completed test leotard... FRONT

BACK

As I suspected, the leotard was too short when she tried it on. But that's okay...this was just a test and I will make it longer when I go to do the real thing. We also discussed how low she wants the back opening, and I made a note as to how many inches down I will need to cut the back. The front will be cut competely differently, and I will handle that later. Laura [ 01-07-2002: Message edited by: Laura La Gassa ] |

| Championship Registered:: 12-19-2000 Posts: 1328 | Step Three: Choosing a Fabric and a Pattern This probably could/should have been done as an earlier step, but I just got to it today. There are hardly any good patterns for fancy dresses made from stretch knits. So, you will need to improvise by choosing a fabric designed for woven fabrics and then sizing down from there. By sizing down, I mean choosing a pattern size that is smaller than what you would usually wear to take account for the stretch fabric. The scientific way of doing this is to open up a pattern and read the "finished measurements" for the waist, hips and bust. This is usually printed directly on the pattern, not in the instructions, which means you'll have to practically take the pattern apart to find it. This is not looked upon well in fabric stores :-) If you do open up the pattern to look, you will want to cut the size which has finished measurements a little smaller than your real measurements. To avoid nasty looks in fabric stores, I use a sort of rule of thumb to chose the pattern size. First, I compare the measurements to the sizes in the BACK of the pattern catalog. Each pattern catalog has a measurement chart to help you decide which size pattern to choose. Do not be alarmed if your measurements translate into something much larger than your usual dress size...dress sizes for ready-to-wear clothes have enlarged over the years due to a marketing concept called "vanity sizing" which I won't go in to now. Suffice to say that, once upon a time, the sizes in the pattern catalogs used to match up to ready-to-wear sizes. Anyway, say your pattern size reads out as a (GASP) 14. Subtract 4 sizes from that (8 numbers....14 - 8 = 6). You will PROBABLY need to use the pattern in a size 6 to get the right fit when converting from woven to stretch fabrics. Using Swivel as an example, I looked in the back of the McCalls pattern guide and found out that she would take a 12 (as a comparison, she wears size 5 pants in ready-to-wear). I subtracted 4 sizes (8 numbers) and decided I'd better pick up a size 4 pattern for her. Finding patterns that small is difficult. Most pattern makers use 6 or 8 as their smallest size..which is fine if you are working with woven fabrics, but doesn't quite suit our purposes here. Fortunately I found a princess-seamed dress pattern I could use. While you're at the fabric store buying the pattern, you should also picked up thread (get one spool more than you think you need, 'cause you'll need it anyway), several yards of 3/8" wide "swimsuit" elastic, half a yard of 1/4" elastic, and pin-in bra cups (also called "molded") in the appropriate cup size. Note that I didn't mention anything about a zipper. I hate zippers and will not be using one in this project. Oh, and if you don't have fabric, get some :-) I already had it so that's why I haven't mentioned it until now. I'm a big fan of slinky, but some people don't like it and have a difficult time sewing with it. I've never had any problems. I like it because it stretches crosswise but not really lengthwise, so it's great for using my usual "convert woven to stretch" method of making ballgowns. If you get something with 4-way stretch, make sure it is relatively stable -- like stretch velvet or swimsuit lycra. You don't want the dress to stretch too much in the vertical because of its own weight! Buy one more yard of fabric than you think you will need in case you make a mistake. Which brings up a question: how much will you need? The information on the pattern won't be much help because you are going to flare out the skirts to make them full enough for ballroom, thus changing their layout calculations. As a rule of thumb, I say you need 10 yards to make a dress -- although if the fabric is 60" wide I've been known to get a dress done with less than 7 yards. Laura [ 01-07-2002: Message edited by: Laura La Gassa ] |

| PreBronze Location: St. Louis, MO Registered:: 06-16-2001 Posts: 95 | Laura,(or dancescape) I can't open the pictures and I really wanna see them. Any suggestions? |

| Silver Location: Maryland, U.S.A. Registered:: 04-13-2001 Posts: 401 | Hmmmm, something has changed. I could see them earlier today, but now I can't see them either. |

| Championship Registered:: 12-19-2000 Posts: 1328 | Don't worry, the pictures will come back. We're having a little bit of server trouble, which is why they aren't showing up. I'm pretty sure my hubby is working on it even as I write this :-) Laura |

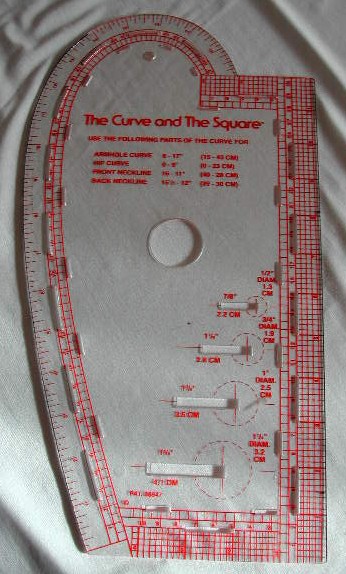

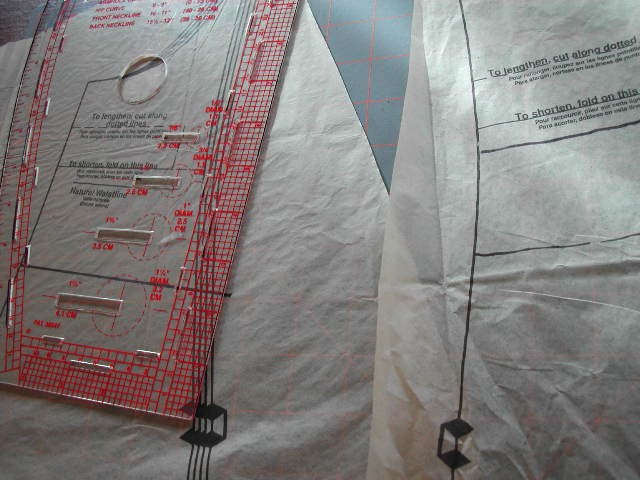

| Championship Registered:: 12-19-2000 Posts: 1328 | Step Four: Preparing the Pattern At this point you should have a pattern and have made an educated guess as to which size you are going to cut out. You should also have the fabric, a Sharpie marking pen, something to cut with (I prefer a rotary cutter and a mat), a tape measure, scotch tape, tissue paper, and a dressmaker's curve. You should also have a basic leotard pattern, properly fitted, from the previous step. A dressmaker's curve is indispensable! If you don't know what one is, this is what mine looks like:

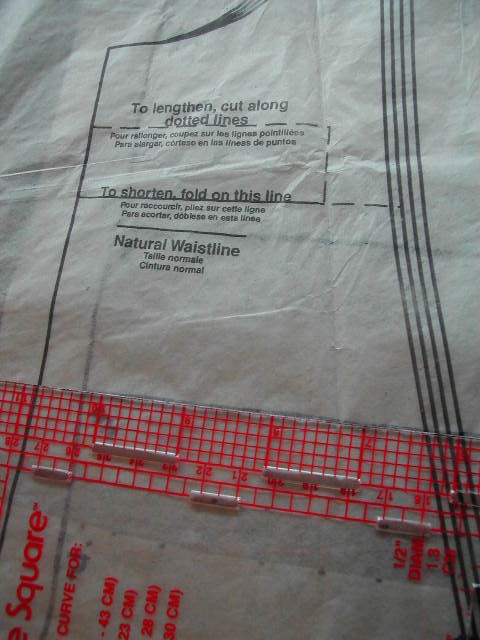

Get one if you don't have one! Start out by separating the patten pieces you will be using from the rest of the pattern. If you are doing a princess-seamed dress, you should have four pieces: front, side front, back and side back. Some of the pieces will be marked with a waistline, some won't. If you're lucky, they ALL will be, but if not it helps to guesstimate where the waistline is on all pieces. Let's say that your side back piece is not marked with a waistline, but the back piece is. Lay the pattern piece down, and lay the back piece next to it, oriented so that the tops are facing in the same direction and so that the notches (the pointy bits that stick out past the cutting line) are near each other. Now, measure up from the center of the notch for the size you are cutting to the waistline on the center back piece. The waistline on the side back piece will fall just about the same number of inches up from the matching notch on the side back piece. I hope the following picture will help:

Now that you've marked the waistlines, it also helps to mark the hiplines. Start with your back piece. To find the hipline, lay the back pattern Having these markings will help when it comes time to "flare" out the pattern piece to create the fullness in the skirt if you are making a dress from long panels with no godets. (Godets are the triangles of fabric that you sometimes see inserted into ballgown skirts.) I guess I should back up here...I started writing these thinking I would discuss making a dress without godets, but it just so happens that the dress I'm working on requires godets. Sorry if this gets confusing...but anyway, if you are making a dress with godets then you probably should have started from a straight "sheath" style princess-seamed dress in order to get the right shape for the dress before the godets are inserted. If you are not making godets then you can start from any princess-seamed pattern and then flare out the panels for the required fullness. I will briefly discuss flaring out the panels, but have no pictures of this step. (1) Adjust the length of the pattern on the "lengthen or shorten here" lines so that the pattern is about 2 inches shorter from the waist to the hem as the "waist to floor" measurement. (2) Find the center of the waistline on (3) In general, panel cut dresses are about 14-20 feet around the hem these days. Let's use 16 feet for this example, 'cause it's easy on the math. To get a 16 foot hem with an 8 panel dress, you will need to make sure the bottom of each panel is about 2 feet wide. So, measure out one foot in each direction from that mark you just made on the hem. At this point you may notice that the lines you are drawing extened past the edge of the pattern tissue. Use tape and your extra tissue paper to add on so that you can draw the lines you need. (4) Now connect the new seam line you just marked back up to the rest of the dress. Most people look best when the dress is flared out from the hips or slightly lower. Say you want to flare the dress out from the hips...so connect the hip line where it intersects the edge of the pattern with the mark you just made. (5) You'll see that you'll get an angle rather than a smooth curve at the hipline. Use the dressmaker's curve to smooth this out. Ok, now you've flared out the dress. For those of you not doing this, please rejoin me as I continue on :-) If you haven't already done so, adjust your pattern for length as described in step #1, above. The next step -- and this is optional but I do this to preserve the original pattern -- is to tape some sheets of tissue paper together and trace a new copy of your altered pattern, in the size you will be using. You will use this copy to cut out the fabric. Don't forget to mark any notches, darts, dots, or other important pattern markings when making the tracing. You should now be ready to cut out the underdress (if you're doing godets) or the main dress. It is very important when cutting out to make sure that you lay out the pattern pieces so that the stretchiest direction of the fabric goes ACROSS the body. Also, if you are cutting on velvet, make sure the nap lays flat from top to bottom on all pieces. What is nap? Pet the velvet...you'll see it stands up if you pet it one way and lays down if you pet it the other. You want the nap to lay down flat if you pet from what would be the top of the pattern piece to the bottom. Cut everything out, making sure to follow the notches for your size. After you've cut, keep each piece with its pattern piece so that you can properly identify the pieces when you start to sew. Laura [ 01-09-2002: Message edited by: Laura La Gassa ] |

| Championship Registered:: 12-19-2000 Posts: 1328 | Step Five: Sewing the (Under)dress Follow the directions on the pattern for sewing together the pattern pieces. Use a long and wide stitch so you can rip out the seam if it's wrong. I set my stitch length to 3.0 and my stitch width to 3.0...you will have to decide for yourself what settings to use on your machine. Sew all vertical seams, plus the shoulder seams. Do not finish off the neckline, armholes or hem, and do not add any sleeves yet. You'll want to fit the dress and make adjustments before doing any more work. The underdress for the gown with godets should hang down to about mid-thigh, where a chiffon underskirt that matches the godets will be attached. When I cut out the underdress I only cut the pattern pieces long enough to reach above Swivel's knees. When she trys on the dress I will mark the final length of the underdress. And here it is:

When I put the dress on the fitting dummy I saw that there's a very good chance that the dress is too big. Well, that's what fittings are for :-) If the dress is too big you can take it in by resewing the existing seams to the inside of their present location, and then trimming off the excess fabric. If the dress is too small you can let out existing seams. If the dress is WAY too small you might have to start over :-( Laura [ 01-08-2002: Message edited by: Laura La Gassa ] |

| PreBronze Registered:: 07-06-2001 Posts: 235 | Laura, I just want to say how fabulous I think this thread is. It's so very generous of you to prepare such a thorough description, complete with pictures of the dress making process. I'm also enjoying Sew sew's thread about the trials and tribulations of her project. Between the two of you I'm inspired to embark on a new project myself. J |

| Powered by Social Strata | Page 1 2 3 4 ... 12 |

| Please Wait. Your request is being processed... |

|

forums.danceScape.com

forums.danceScape.com  Forums - Live, Love, Laugh ... Dance!

Forums - Live, Love, Laugh ... Dance!  danceScape SkyhiClub Lounge: Welcome to the Skyhi Life!

danceScape SkyhiClub Lounge: Welcome to the Skyhi Life!  FASHION

FASHION  The Dress Project -- Step-by-Step Ballgown Construction

The Dress Project -- Step-by-Step Ballgown Construction

Tel: +1 (905) 633-8808 E-mail: info@dancescape.com